We are often asked about the application methods and why we use one over another so I have outlined below the different types of application, what they are generally used for and why. This follows on from Gold and Metal Leaf Part 1 where I explain the different types of metal leaf. I'm thinking this may need a part 3 to show you some of the amazing and outrageous extra bits and bobs there are available. Meantime let me explain why size REALLY does matters

Size

Size is the material used to stick the leaf to the surface.

|

| a selection of Oil Sizes |

Oil Gilding

Oil gilding is the most common form of architectural gilding, highly durable and providing the substrate is prepared correctly and the size and gold applied correctly, a surface that is gilded with a high carat gold will have an incredible life span where the substrate is more likely to break down before the gold will.

The process involves using an oil (solvent borne) size. The material is similar to a yacht varnish in appearance. It comes in different drying times (3-4 hour, 8 hour, 12hr and 24hr). Which one the gilder will use depends on the size of the project and the brilliance of gold required but also on site conditions. The slower the set of the size, the brighter the gold will be but if site conditions are dusty then the slower drying sizes may pick up dust and dirt.

The gold is applied when it just becomes tacky enough….an experienced gilder knows when this is and how to manage the size types to maximise the gilding time in the day. The time each size is going to come tack is indicated by the “hours” but it is variable depending on atmospheric conditions - humidity and cold can slow the setting time, in hot dry conditions the size may come to tack early

Benefits of Oil Size –

- Oil size has self-levelling qualities and sets to a smooth, glossy surface.

- Oil size cures to a hard durable bond for the gold.

- Oil size will adhere and give good intercoat adhesion to most substrates well. We advise a substrate of high quality water based eggshell for all interior work. Alkyd eggshell or gloss for exterior projects

- Oil size is not affected after curing by damp

Disadvantages of Oil Size –

- Slow drying so it tends to attract dust however goodhousekeeping and timing can minimising this

- Limited working time which means that it may not be ideal for very, very large areas and also means careful management of time

- Affected by weather conditions during application however a skilled gilder can manage these.

|

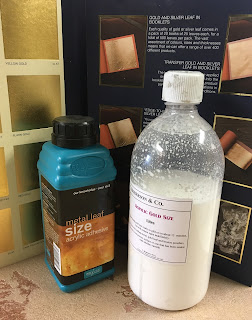

| 2 different acrylic size products |

Acrylic Size using the Oil Gilding Technique

Acrylic size is a contemporary material usually associated more with “hobby” crafts however it does have its use in interior architectural gilding.

Acrylic size is a contemporary material usually associated more with “hobby” crafts however it does have its use in interior architectural gilding.

It is similar in appearance to a thin PVA glue and it dries within about 15 minutes to a permanently sticky finish. There is no complete drying of the material that can be bought in the UK, although Marlow Demars has kindly pointed out in the comments below - there are some US products that dry hard.

Benefits of Acrylic Size –

Benefits of Acrylic Size –

- The main advantage to the material is you can size a very large area such as a ceiling and spread the work over a period of days rather than having to complete within very tight drying times. We recommend it for areas that will not be subject to traffic like ceiling areas.

- It is better for Copper Metal Leaf as it is a more inert less complex product and less likely to encourage oxidising

- It is water based which may suit some site conditions where solvents are strictly controlled

- If the leaf needs to be varnished then you don’t have to wait for curing.

Disadvantages of Acrylic Size –

- The material holds brush/application marks and doesn’t level off

- The material never dries, it stays soft and sticky under the gold so if it gets scratched what will be revealed is a dust attracting sticky layer. It is also much more easily damaged because of this

- The material will deteriorate quickly if moisture gets into the area, because this material scratches through easily then this happens more readily in high traffic areas than if oil size is used

- Acrylic sizes reduces the sheen

- Poor adhesion and a tendency to ciss over oil based paints

|

| The Absolute Maestro of Water Gilding and Verre Eglomise Gareth Evans of Watergilders.com |

Water Gilding

Water gilding produces the highest shine but because of the very complex and slow preparation of the surface required, the cost is generally prohibitive for most architectural purposes. It is a technique generally used for high quality furniture and frames and for Verre Eglomise (gilding on glass). The Size used is Gelatin

Instacol

Instacol is a German Sizing system that offers the gilder a method of achieving a very well bonded high sheen look similar to that achieve with a slow set oil size and can even give the brilliance of Water Gilding. It is entirely water based and is a two stage system which controls when the size will become ready to gild reducing the chance of dust pick up.

There are many advantages to this system but it is a more expensive system than traditional oil size and because it is a two-stage system then sizing is double the labour.

We are happy to discuss Instacol with you and offer you costings if this system would suit your project best.

Varnishing Leaf

High carat leaf and those metals that are not prone to tarnishing do not require varnishing and in fact the varnish can reduce the sheen and appearance of the material. All architectural gilding done with low carat metals need to be sealed. There are instances where due to high traffic that all metal leaf needs varnishing to increase protection. These may be instances when we would consider recommending metal leaf as opposed to Gold Leaf.

We now produce a metal leaf sealer called Whitson's Universal Lacquer for this specific purpose and this can be found at www.caitwhitson.com

Please feel free to ask questions, post comments etc and if you'd like to talk to us about a gilding project give Cait or Gibson a call on 01738 587600